Professions connected with computer technologies have become high-in-demand quite recently, but we can already say that they have taken a firm place among the others. And we are talking not only about jobs in IT companies, but also in construction companies, industrial and agricultural enterprises. SUSU is one of the leaders in the process of training specialists who are highly qualified to work with complex equipment, create models in programs and improve technological processes. So, there are many programmes for applicants who wish to obtain a perspective profession.

The sphere of working with operating equipment can be divided into levels. According to the Vice-Rector for Academic Affairs of SUSU, Professor Andrey Radionov, there are developers who are creating new types of “smart machines”, process automation specialists responsible for the control system, and mechatronics specialists who put complex mechanisms into practice.

Mechatronics: the Most Profitable Profession in Russia and in the World

Personnel consisting of robots at a plant does not seem that surreal anymore. Smart machines perform asserted tasks profoundly, they do not get tired but require qualified creators and managers.

In general, mechatronics is the integration of mechanics, electrical machines, automation equipment, power electronics, microprocessor technology and software. To put it simply, a mechatronics engineer is a versatile worker needed at any enterprise. This specialist changes not only machines, but also processes, and builds a "smart automation", which saves financial and human resources. According to the report by the Ministry of Labour, mechatronics is the most profitable profession in Russia and in the world.

SUSU offers new programmes and, what is more important, the centres for acquiring practical skills for training of mechatronics engineers.

The Department of Mechatronics and Automation invites applicants to a full-time study programme 15.03.06 Mechatronics and Robotics (27 state-funded places).

Smart Automation

Nowadays, it does not seem as a surprise to anyone that a complex process can be started by pressing only a single button. This is how a washing machine or a microwave starts to work. But the process is much more difficult at an enterprise, that is why the specialists that manage the control system are always valued.

“In modern conditions, automation is not just an algorithmic description and exclusion of a person from technological operations. Today, the elements of artificial intelligence are laid down at this level, turning into algorithms allowing to optimize the process without human intervention,” explains Andrei Radionov. “Any equipment is a set of actuating mechanisms of various nature, which are managed by industrial controllers.”

Students, who are learning automation, comprehend the principles of industrial cybernetics and control algorithms that allow an enterprise or a separate complex to work in an autonomous mode.

At the laboratories, students can work on industrial equipment by the major manufacturers in the field of automation: Siemens, Emerson, and others.

The Department of Mechatronics and Automation invites applicants to a full-time study programme 15.03.04 Automation of Technological Processes and Production (27 state-funded places).

Engineering of the Future

Another trending field is Engineering of Technological Equipment. This is not an automation of processes, it is about the creation of new technologies. And there is already a queue for such specialists.

At SUSU, students study computer modelling, 3D prototyping, additive technologies in mechanical engineering, computer-aided design of technological machines, technological processes in mechanical engineering, modern methods of processing of materials, systems for engineering analysis of technological machines. They become confident users of packages such as ANSYS, SOLIDWORKS, KOMPAS-3D, AutoCAD, etc.

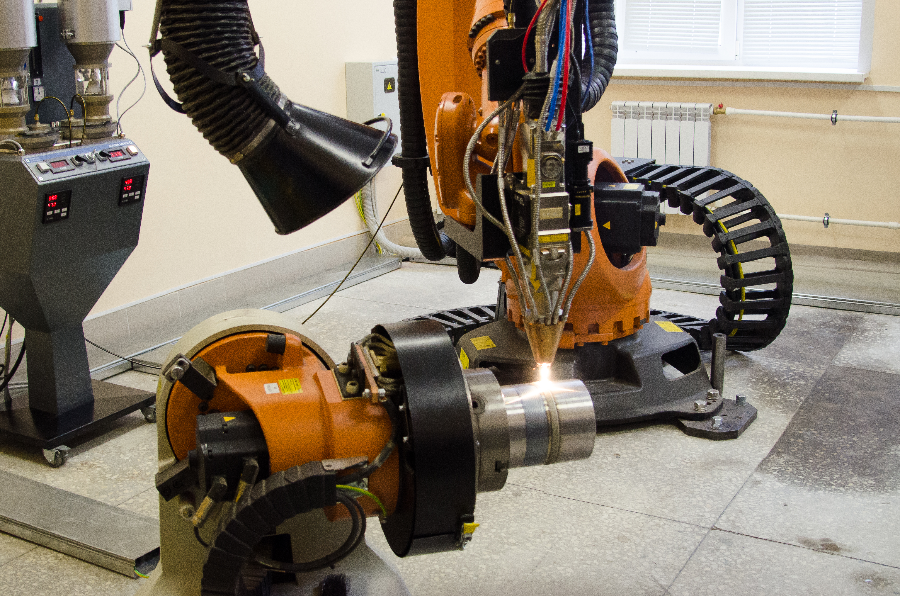

The Department of Machines and Technology of Metal Treatment under Pressure provides its own 3D prototyping laboratory, fitted with such equipment as 3D printers of various types, a laser engraver, a CNC milling machine, a hydraulic press; the students of the department have unlimited access to the equipment of the Laboratory of Mechanics, Laser Processes and Digital Production Technologies with a robotic laser cladding installation, and a detonation spraying complex.

The staff of the department, consisting of many young academics and postgraduate students, who conduct a big number of commercial projects with the help of the most talented students. The collaboration with the world leader in the production of metallurgical equipment, SMS Group, Germany, and the Double Degree program with the National Engineering School of Saint-Etienne, ENISE, France, allows students to take internships and study abroad.

The Master’s degree programmes, such as Digital Technologies in Rolling Production and Their Metallurgical Support, Additive Technologies and Design and Maintenance of Technological Machines and Units opens an opportunity for the graduates of the Bachelor’s degree programmes to stay at the department for two more years, deepen the knowledge and broaden the horizon.

The Department of Machines and Processes of Pressure Metal Working invites applicants to a full-time study programme 15.03.02 Technological Machines and Equipment; Engineering of Technological Equipment profile (27 state-funded places).

Welcome to the Institute of Engineering and Technology

The fields of training for major manufacturing companies are united at the SUSU Institute of Engineering and Technology. Today, the task set by the President of our country is being solved there: the digitalization of industry and transition to a new technological revolution, Industry 4.0.

New tasks required a completely different approach to the educational process, and South Ural State University was one of the first to respond to the changes. The programme was revised and an ultra-modern base with all the necessary equipment was created. That is why the skills gained over four years of studying will not become outdated even after a few decades.

SUSU academic staff focused on a comprehensive approach, that is, a close connection of science and design and technological activities, cross-disciplinary work when the issues of materials, mechanics, energy, transportation and manufacturing technologies are organizationally combined, and at design work that provides practical skills.

The Institute of Engineering and Technology features the Youth Design Bureau, where students in a team conduct research projects closely collaborating with major companies. SUSU partners in personnel training and the future employers are enterprises of ROSCOSMOS, ROSTEKH, ROSATOM state corporations; big companies of other associations and design organisations: VIAM, IMASHRAN; as well as international partners: SMS Group, Emerson, Siemens.