Dynamic measurements are measurements of processes that occur so quickly that conventional technical means cannot detect them fully. However, thanks to new innovative technologies used in the Laboratory of Dynamic Measurements, scientists of South Ural State University are able to obtain more accurate information about what can happen during very fast processes. The research work is conducted jointly with the major industrial enterprises of our region.

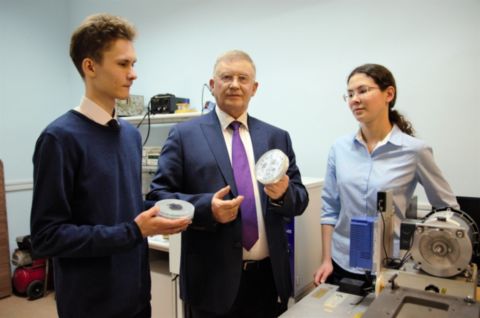

The Laboratory of Dynamic Measurements was created in 2018 at the initiative of the President of SUSU (at that time the Rector of the university), Doctor of Sciences (Engineering), Professor Aleksandr Shestakov, who is the Head of the Scientific School on the Theory of Dynamic Measurements of the Department of Informational and Measuring Technology of the SUSU School of Electronic Engineering and Computer Science.

Research in the field of dynamic measurements allows to study fast processes and phenomena that occur in a very short time, for example, impulse mechanical actions, pressure surges, etc. Accurate measurements of these processes can help increase the efficiency of the developed equipment and improve the safety of production processes. The direction of scientific research in the laboratory is based on the application and development of the methods of automatic control theory in the problems of measurement dynamics. This approach was proposed by Professor Aleksandr Shestakov and was used in his doctoral dissertation and candidate dissertations of his students. Based on the results of defended works, the Methods of the Theory of Automatic Control in Dynamic Measurements monograph (Chelyabinsk: SUSU Publishing Centre, 2013. – p. 256) was published. Currently, this method is recognized as one of the three approaches in the development of dynamic measurements.

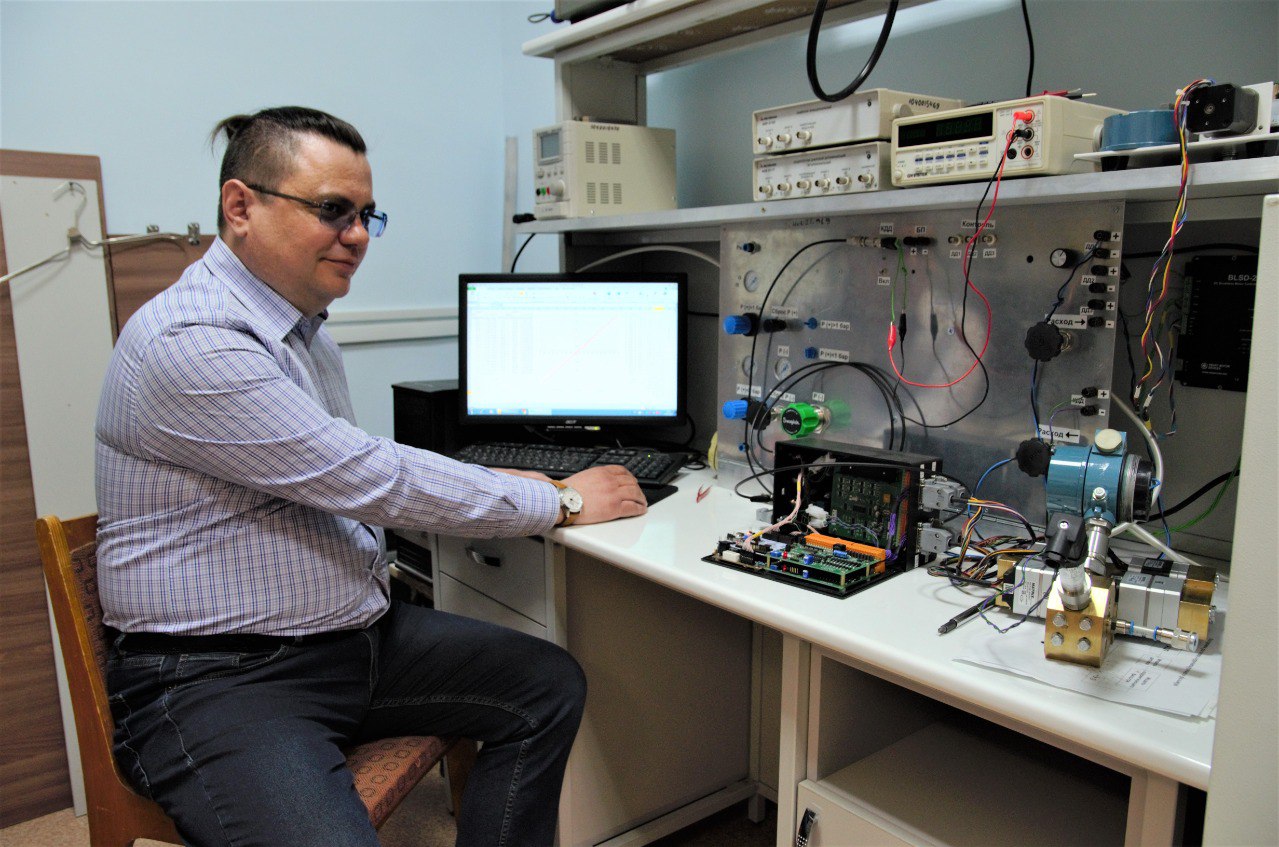

To conduct experiments, the laboratory is fitted with certified equipment allowing to confirm the results of theoretical work, algorithms and programs.

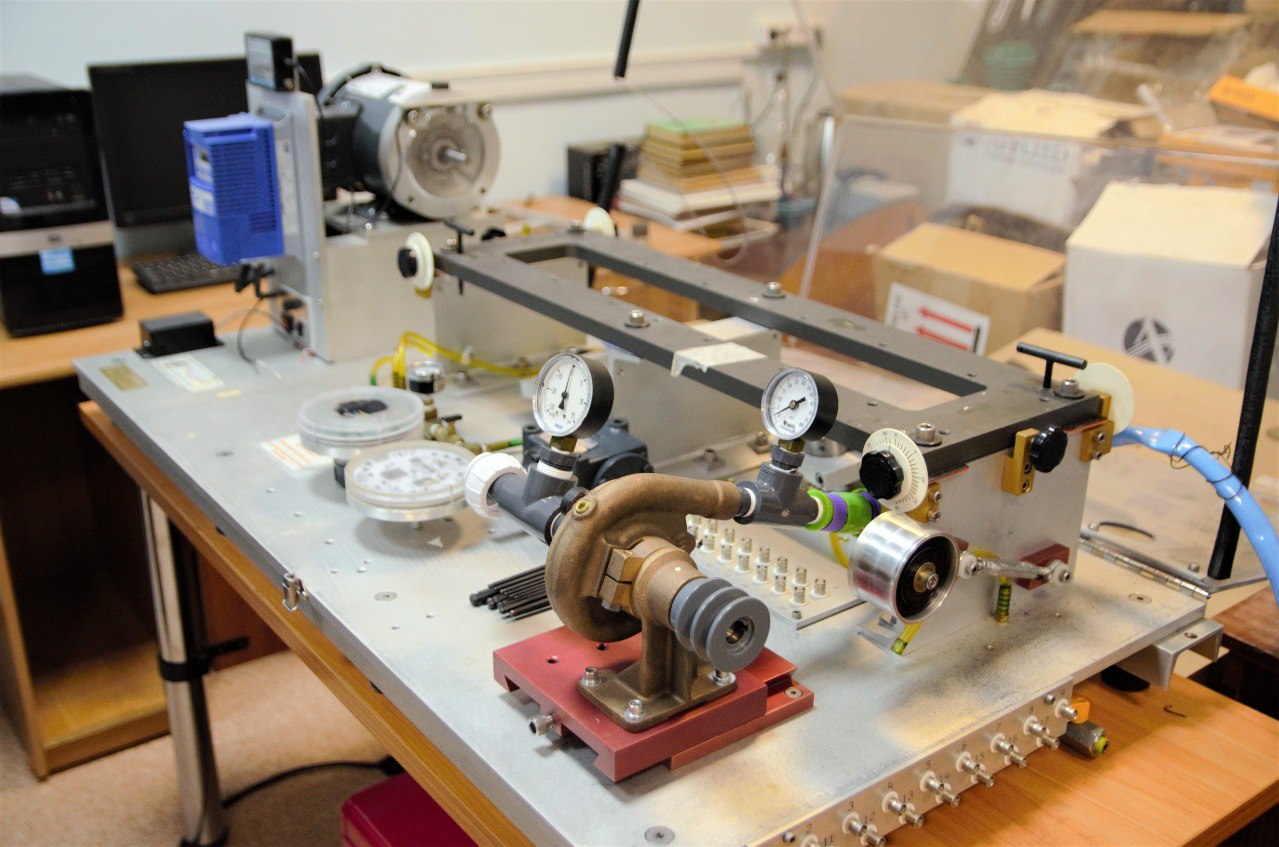

“The laboratory is built around a unique stand of pulsating pressures, designed and created by the engineer of the SUSU Research Laboratory for Self-Validating Sensors, Systems, and Advanced Instrumentation Systems Grigoriy Grudtsinov. The stand is designed to study the dynamic characteristics of pressure sensors using test signals of impulse pressure of various shapes (sinusoidal, rectangular, sawtooth, as well as random effects). Also, using a climatic chamber, the stand allows to test pressure sensors in a wide temperature range,” said the research advisor of the laboratory Aleksandr Shestakov.

The main task of creating such a stand is practical testing of the working capacity and efficiency of the developed methods, models and algorithms for processing dynamic measurements data within the framework of the scientific direction of the department. The activities of the laboratory are closely connected with those of the Laboratory of Self-diagnostics of Measuring Instruments and Technical Systems.

Now the development of an experimental stand-simulator of sensor equipment is being completed to study the algorithms for processing data from dynamic measurements in a wide dynamic range and under various random effects. The use of this stand will make it possible to evaluate the quality of dynamic measurement data processing algorithms.

Since 2022, jointly with the industrial partner of Metran Industrial Group, the laboratory has been implementing a project on studying the dynamic characteristics of Metran-150 pressure sensors and developing algorithms for improving these characteristics using deep mathematical processing of the output signals of the sensors without changing their design.

The staff members of the laboratory are also implementing the project on Development of a System of Intellectual Analysis and Forecasting of Trends in the Development of Damage to Equipment of the Rolling Workshop-11 Rolling Line Based on Information from Sensors for Diagnosing the State of Technological Equipment and Process Parameters”, being conducted in the interests of Magnitogorsk Iron & Steel Works.

The research in the laboratory of dynamic measurements is conducted within the frameworks of the Priority 2030 program (the Science and Universities National Project) and is a part of the Intelligent Manufacturing strategic project.

The topic of dynamic measurements is significant and promising on the scale of international research. So, in 2024, it is planned to hold a special session on this topic at the Congress of the International Measurement Confederation (IMEKO) in Hamburg, Germany. The forum will bring together the world’s leading experts who work in various fields of measurements.

South Ural State University is a university of transformations, where innovative research is conducted in most of the priority fields of science and technology development. In accordance with the strategy of scientific and technological development of the Russian Federation, the university is focused on the development of big scientific interdisciplinary projects in the field of digital industry, materials science, and ecology. In 2021 SUSU became the winner in the competition under the Priority 2030 program. The university acts as a regional project office of the World-class Ural Interregional Research and Education Centre (UIREC), which is aimed at solving the tasks of the Science and Universities National Project.

Mass media about us: SUSU Laboratory Conducts Accurate Measurements of Fast Processes for Industries

Read our news: