“Today cybernetics is everywhere; and what seemed science fiction yesterday is a mere trifle now!” These lines by a famous poet and writer Eduard Asadov could also relate to modern industry: the advanced businesses implement automation in all the fields of their activity, and shift to the technologies of Industry 4.0. That is why they also require from their employees to be in command of the most advanced knowledge, new competences and approaches to work. Meeting the demands of the times, the SUSU Institute of Engineering and Technology is training engineers of the new generation. Director of the Institute of Engineering and Technology Sergei Vaulin shares on how education under the university’s engineering programmes is organized today, and what prospects open for the graduates.

— The Institute of Engineering and Technology has always been proud to be training high-class engineering specialists. One might ask: ‘Why change anything?’ How do the new trends in industry affect the education of the future engineers?

— The scheme of the driving forces, which more the world economy forward, changes every other decade in the world. Today, this role is played by IT technologies, which penetrate into all industrial spheres and demand their complete readjustment. If you are part of that process, then you are in the forefront, but if you live in some parallel reality and not interested in such things, then other people will be building global business and earn money. That is why a new global task has arisen in the world’s industry: to complete transition to the Fourth Industrial Revolution. Such term as Industry 4.0 appears and all the concepts related to it: Internet of Things, Big Data, ad virtual and augmented reality. It is becoming obligatory for a modern production to have its digital twin, which will allow to predict and assess the results, and determine the optimal scenarios of development. To achieve that, enterprises are being equipped with state-of-the-art sensors transmitting information into data clouds, and once this information is processed, recommendations are formed and possible action scenarios are elaborated. The automated processing of requests within the Internet of Things, the expanding of the scale of unique orders, and reduction of their fulfilment terms – all of these things require to fundamentally change the technologies and process systems at enterprises. Within a short period of time the production will most likely undergo dramatic changes, and that means that we must train a new type of engineers: specialists with a whole complex of new knowledge and skills. Of course, we still take into account the current needs of enterprises, but we also try looking ahead so that we could train engineers of the future. In this context we have based the strategy of general development of work being carried out by the Institute of Engineering and Technology on the digitalization of industry and have formulated this strategy as a transition from Engineering 3.0 to Industry 4.0.

— The Institute of Engineering and Technology is of the biggest institutes of SUSU. Could you please give us more details on its structure?

— Approximately by the middle of this decade, South Ural State University has grown into a major corporation. However, its organizational structure remained the same as in the times when there were over twenty faculties in the university. So, a decision was made to create a new university structure, and to combine similar fields of research and engineering activity into schools and institutes in order to make their work more efficient. Thus, the fields related to basic industrial sectors — from metallurgy to aerospace engineering — were united under the Institute of Engineering and Technology. Those included material science and metallurgy, mechanical engineering, power engineering, motor vehicles, and aerospace engineering. Five faculties were formed: Faculty of Material Science and Metallurgical Technology; Mechanical and Technology Faculty; Power Engineering Faculty; Automobile and Tractor Faculty; and Faculty of Aerospace Engineering. And the sixth faculty, Extramural Faculty, offers studies in a part-time mode. It is a well-known fact that some of our faculties date back to the very time of the establishment of our university, and others came into being later as a response to the industrial demands of our country. This way, we have a rich and glorious history, huge experience and recognition, and at the same time we dynamically develop and react to all the changes happening in the world.

— What are the trends of development of each faculty?

— Everyone remembers the year of 2013, when an asteroid from space dropped in Chelyabinsk and caused quite a lot of trouble. SUSU seriously suffered from the fall of this space body back then. So, asteroid security does mean something to us. We took this field, a strategic one for our university, as a basis for the development of the Faculty of Aerospace Engineering.

— What does asteroid security mean?

— At modern scale of urbanization there is a higher possibility that such tragedy might happen again. To prevent this, we must detect a space object flying towards us early, at the distance of millions of kilometres from us, and send a spacecraft to this object, to study its surface and decide on what to do with it: destroy it or deviate its trajectory, and to calculate where it might fall. We involve students of all the years of study to work on such global projects. For that purpose we created an Asteroid Youth Design Bureau, where young specialists and students gather several times a week, and under the guidance of more experienced senior mentors deal with solving big-scale tasks. The research fellows and students of the Faculty of Aerospace Engineering are working at the Design Bureau on engineering promising spacecrafts for delivering equipment to a space body with small gravitational field. The idea is that such transport and energy module could fly up to an asteroid and send there a probe with equipment from the distance of 100 km. Within this project, developments are being carried out on low-thrust rocket engines, “smart materials” and “smart structures”. For instance, we are planning on engineering power units with the help of additive technologies, with annular combustion chambers and nozzles.

Besides the asteroid security, there exists a problem of cleaning the near-Earth space off the space debris, which pose a threat of damage to spacecrafts every day. Debris move along the orbit at the speed of 8 km/sec: not a single missile could fly that fast on Earth. And if debris collide with a spacecraft on a head-on course, their speed doubles! Even the smallest element could pierce through the spacecraft skin. You can’t control the movement of debris on the orbit, so to cope with them you also need to be able to detect them, fly up to them, capture them and forward to the Earth surface, so that they could safely burn in the atmosphere. So, we could use debris to test our technologies of fighting against small space objects. We have tried to combine all of these aspects into one programme called Clean Space.

.jpg) .

..jpg)

— What tasks under Industry 4.0 are being solved at other faculties of the Institute of Engineering and Technology?

— The main vector of the scientific and engineering development of the Automobile and Tractor Faculty is the smart transport for a smart city. That includes engineering of self-driving cars and public transport, as well as creation of power-efficient engines.

Engineering of powerful engines for heavy off-road vehicles is a field that is also still being worked on at the Faculty. Moreover, the student Design Bureau is creating race cars for Formula Student competitions.

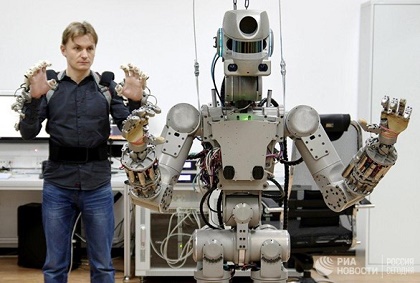

At the Mechanical and Technology Faculty, the main field of development are digital technologies and robotic systems in mechanical engineering. We deal with not only industrial robotics, but also with any computer-controlled metal-cutting equipment. We also work with additive technologies, among which is 3D printing, for instance. Currently we are trying to combine those with the new principles of mechanical processing of parts with complex surfaces. This will allow not only to produce goods more cost-effectively, but also to ensure high quality to them at the same time.

The key field of the Faculty of Material Science and Metallurgical Technology are the new materials and digital technologies of metallurgical production, in particular in terms of pipe- and sheet-rolling. Digitalization of all technological processes: pyrometallurgical processes, processes of welding and pressure metal working taken in conjunction with forming the characteristics of the materials themselves – all of that falls within the field of work at this Faculty.

Power Engineering Faculty is working in the field of digital distributed power engineering and smart electric drive. It is also considering the possibilities of using additive technologies to manufacture rotors and parts of stators of electric machines. Usually, these are produced from wiring, but 3D-printed items have already been obtained as well.

.jpg)

.jpg)

— And how is the system of training “specialists of the future” organized today?

— The times challenge us and demand a new approach to training engineers — project-based learning. I have already mentioned that our faculties are performing their scientific and engineering research in most advanced and promising fields of development in the world. We receive orders mostly from well-known enterprises – our strategic partners. Therefore, our students are participating in real projects of those companies. Through performing this work, they obtain additional knowledge, gain new skills and real practical experience. As a result, our graduates step up to a whole new level, and enterprises gain specialists and even teams trained and ready to work on their specific tasks.

Another important component is the elite training for talented students, who demonstrate excellent performance in studies, participate in Olympiads, score high at the Unified State Examination, and wish to successfully fulfil their potential in the future. Starting from the very first year of their studies, they are offered advanced learning of mathematics, English, and of a number of other disciplines; they are invited to participate in research works, and such students are also involved in serious projects. We try to work with them on an individual basis, cover all aspects of what they wish for and what they capable of, so that, on the one hand they could fully unlock their potential, and on the other hand, they learned how to work in a team and could confidently develop in their professional activities.

— Is project-based learning mandatory for all students?

— Project-based learning of the Institute of Engineering and Technology is intended for Master’s degree students from their first year of study and for Specialist students from their 3rd year of study who are willing and, what’s most important, capable of working on a project. Without a doubt, traditional education remains at the university as well. All students have different abilities, and we try to take it into account and adjust so that everyone could acquire skills required by standards and find one’s optimal place in professional activity.

— Working over projects is a team effort. Does it mean bringing together various disciplines and knowledge?

— The goal of the Institute of Engineering and Technology is to educate engineers with not only fundamental knowledge in their sphere but with other knowledge as well. This also is the goal of project-based learning. For example, the project called “Electric Race Car” brought together students of the Automobile and Tractor Faculty and the Faculty of Energy and Power Engineering. They’ve got an assignment to independently design and produce a dynamic, efficient, noiseless and environmentally safe race car. With the use of supercomputer with necessary licensed software and the collective use centres for manufacture of complex units and details, students managed to develop a model of a unique electric motor that complies with all the specified requirements. Having combined the efforts of all specialists, students produced a real prototype model. The project of the electric race car will be presented at the end of 2019 within All-Russian Science-and-Technology Competition in Moscow, which is a preparatory stage before the Formula Student competition in Europe.

— Проектное обучение касается всех студентов?

— В проектном обучении Политехнического института участвуют студенты магистратуры с первого курса и специалитета, начиная с 3 курса, которые имеют такое желание, а главное — способности к проектной работе. Безусловно, традиционное образование в вузе тоже сохраняется. У всех студентов разные способности, и мы стараемся это учитывать и приспосабливаемся так, чтобы каждый смог получить предписанные стандартами компетенции и нашел оптимальное для него место в профессиональной деятельности.

— Работа над проектами — это командный труд, а значит, объединяет разные дисциплины и знания?

—Задача ПИ —воспитать инженера не с одним только фундаментальным знанием своего направления, но и с другими. И это тоже цель проектного обучения. Например, проект «Электроболид» объединил студентов Автотракторного и Энергетического факультетов. Перед ними поставили задачу самостоятельно спроектировать и изготовить динамичный, экономичный, бесшумный и экологически безопасный болид. Используя суперкомпьютер с необходимыми лицензионными программами и центры коллективного пользования для изготовления сложных узлов и деталей, ребятам удалось разработать модель уникального электродвигателя, который удовлетворяет всем указанным требованиям. Объединив усилия всех специалистов, студенты изготовили реальный опытный образец. Проект электроболида представят в конце 2019 года на всероссийском научно-техническом соревновании в Москве, которое является подготовительным этапом Formula Student в Европе.

— А объединяются ли в работе над проектами специалисты Политехнического института и других институтов вуза?

— Есть и такие научные коллаборации. Например, Политех и Архитектурно-строительный институт. Команда приступила к разработке проекта Smart-city. Предполагается, что эта инновационная система управления найдет применение в г. Сатка, который включен в реестр «умных городов» России. Проект, действительно, является мультидисциплинарным по своей сути, так как для каждого изделия необходимо рассчитать экономические характеристики, технические параметры, технологические барьеры, безопасность, управление и многое другое.

Также мы сотрудничаем с Высшей школой электроники и компьютерных наук в выполнении проекта по астероидной безопасности и с Высшей школой экономики и управления – в плане продвижения инновационных продуктов на рынок.

— Do specialists of the Institute of Engineering and Technology combine their efforts with specialists from other Institutes of the University?

— There are such scientific collaborations, for example, between the Institute of Engineering and Technology and the Institute of Architecture and Construction. The team has started working on a project called Smart-city. This innovative control system is supposed to find its application in the city of Satka, which is included in the register of “smart” cities of Russia. The project is indeed multidisciplinary in its essence, because it is necessary to calculate economic characteristics, engineering parameters, technological barriers, safety, control and many other parameters for each product.

We also cooperate with the School of Electrical Engineering and Computer Science in working over the project on asteroid defence, and with the School of Economics and Management in promotion of innovative products on the market.

— Project-based learning assumes multiple internships. Where do students carry out their research, production and experiments?

— All this work is based on our educational and R&D experience as a national research university. In order to provide proper training of an engineer, we needed a considerable number of facilities and resources, and we managed to accumulate them over the last ten years. They are such unique and often one-of-a-kind research and education centres (RECs) of the university society as: Rocket and Space Technology Education Centre named after V.P. Makeyev; Energy-efficient and Resource-efficient Technologies of Diesel Engine Manufacturing for Armoured Vehicles and Engineering Machines Research and Education Centre; Laboratory of Composite Materials and Structures; Mechanical Engineering Laboratory; Laboratory of Physical Simulation of Thermomechanical Processes; Experimental Mechanics Laboratory; Powder Metallurgy Resource Centre; Computer Engineering Centre, etc. And, of course, we use the possibilities of Nanotechnology REC, Supercomputer Simulation Laboratory and other laboratories of the university.

Our facilities and resources keep improving. For example, there are training laboratory test beds with augmented reality being developed at the Institute of Engineering and Technology; they have been implemented into the education process. A project with such a test bed became prize-winner at the IT-BREAKTHROUGH contest in 2017 and took the first place at an engineering competition held in Samara National Research University named after Academician S.P. Korolev.

— Could you make an example of the latest large-scale projects which the Institute of Engineering and Technology worked on with participation of students?

— For the last eight years we have been completing large-scale projects for our strategic partners. For example, together with Turbina Special Design Bureau we have developed and tested a perspective prototype model of a gas-turbine unit which generates 100 kW of electric power. This unit can fit into a KAMAZ truck, get transported and installed in places where there is gas but no power lines, for example, in remote regions of the country or in the Arctic.

For Pribor plant we invented an intelligent computer-aided power system control complex for buildings. Another project was for KAMAZ: we developed power-efficient transmissions for trucks and buses.

These projects featured 50 to 100 people: academics, research fellows, engineers, postgraduates and students. We got a priceless experience of cooperating with enterprises. And the enterprises learned that we can not only teach but also professionally work with engineering and process documentation as well as create and test prototype products.

— Project-based learning provides new perspectives for students, but this requires extra efforts. How do you manage to attract them to this process and get them engaged into science?

— We start working with them while they are still schoolchildren. For students from schools, lyceums and gymnasiums, who are ready to seriously work on research, we offer small projects which are included in strategic directions of development of each Faculty and the Institute as a whole. This is how we attract future students to this sphere, and they try themselves in the role of researchers, inventors and engineers. If they want to fulfil themselves in this sphere – they apply to study in our Institute. It is planned to make teams of schoolchildren to present reports on their project activity at our annual conference of academics, research staff and students and see presentations of other speakers. This means that we bring together different generations and provide creative development of each personality. This is a continuous process of involvement of young people into the most important strategic development of our country – the creation of a digital industry.

Research and engineering work of school children is also organised by Chelyabinsk’s Quantorium, which is geographically located at SUSU and is supervised by our alumnus and academic. In Quantorium, schoolchildren of 7th to 11th grades can work on projects not only theoretically but also practically by implementing their ideas into real items. We have an Engineering School that has been established and is operating for schoolchildren. We continue this development of young people within elite training and project-based learning. And, of course, we keep in touch with our alumni: maintain their qualification level at the Institute of Supplementary Education, attract them as subcontractors to our projects, provide assistance in their professional activity, and supply them with new groups of graduates. Therefore, having come to pursue science, young people stay with us for a long time. And this gives them additional advantages.

— Is there any history of joint projects with schoolchildren?

— We had an idea together with Quantorium to organize an international scientific school on aerospace engineering for students and schoolchildren this summer. This is intended to give young people a chance to discuss asteroid defence at the territory where people really had to deal with this phenomenon. We want schoolchildren to meet university students and learn more about brand-new technologies in the sphere of aerospace engineering, listened to lectures of leading scientists, completed small projects and competed in teams. These teams will feature international students; this fact proves the high and large-scale level of this event. Students will face an unusual task: within 10 to 12 days they will have to design and construct the mockup of an aircraft which could fly to an asteroid and land on its surface without bouncing or any damage.

— Project-based learning had an impact on not only students. Did academics make a step to the new level as well?

— While completing our projects for enterprises, we created new-format research teams which can work on such advanced projects and share their experience with students. These projects got more than a hundred of teaching staff involved. But this is not enough as a hundred is far from the total number of teaching staff at the Institute of Engineering and Technology. Therefore, we elaborated a vocational enhancement programme for such type of activity. Teaching staff, who got such an experience, share it with their colleagues. At the moment, this programme is quite in-demand. As I’ve already said, we have Youth Design Bureaus, where experienced academics taking part in project development work along with young specialists, who see that their senior colleagues can teach them a lot, so they are working hand in hand. This is very precious!

— Does project-based learning has an effect on the university’s relationships with partner enterprises?

— At the Institute of Engineering and Technology, we have not just determined the strategic direction of development and allocated all our tasks around the Faculties, but also created a complex system which is going to ensure continuity of project-based learning of Master’s and Specialist degree students through Youth Design Bureaus up to postgraduate studies and vocational retraining. This is how we become more attractive to employers by offering not just our alumni but also well-trained teams of professionals. Taking into account that there is some work on real perspective tasks assigned by our strategic partners laying in the basis of such a process, we get an absolutely different effect. We perform training of cadre, but we also are developers of new equipment and technologies. These inventions are beneficial for enterprises as they are some additional driving force to their sustainable development and competitiveness on the market of hi-tech products.

Our scientists are not limited by a range of scientific and technical problems of a separate industry. We frequently travel abroad; we have a wide range of contacts with the leaders of scientific and engineering spheres all over the world as well as with our colleagues from other Russian and foreign universities. We have broad daring ideas regarding the perspective directions of development. By cooperating with us, enterprises often discover new horizons of possibilities. Thus, we have a constant multi-resource feedback. Without such a close connection based on real projects implemented by partner enterprises, this project-based learning becomes simply impossible.

— Good specialists are always well-demanded. What enterprises do your alumni build their careers at?

— Without a doubt, high-quality basic education provides a reliable background in life. Future alumni of the Institute of Engineering and Technology acquire all necessary skills for working in the leading enterprises of the country: Roscosmos, Rosatom, RAO EES, Rosseti, Metran, Kamaz, Mechel, Konar, ChTPZ, and many others. Advanced learning of foreign languages gives a chance to get employed to foreign corporations, such as Emerson or SMS group.

Moreover, in the process of studying, many students start to seriously think about establishing their own startup. We always encourage this: the idea to create something new, no matter if it is some product or technology, only makes us happy. If they said before that students in their free time play KVN, now they also work on development of startups.