Additive Manufacturing, or Additive Fabrication (AF), is one of the most dynamically developing areas of digital manufacturing. A team of master’s degree students from the Department of Innovation Management in Business of SUSU School of Economics and Management created an algorithm for analyzing innovative methods of product manufacturing based on the use of additive manufacturing for industrial enterprises.

Additive manufacturing for manufacture development

In the age of innovative economy, time spent for goods manufacture is the most important factor of a business’s success or failure. Therefore, more and more industries start actively mastering AF technologies. Master’s degree students from the Department of Innovation Management in Business, Tatiana Zaytseva, Natalia Oreshkina and Elizaveta Zagrebina, under supervision of Candidate of Engineering Sciences, Associate Professor Viktor Tomashev, became the winners of the Forward to Discoveries contest and obtained grant for conducting research in this area.

“Despite the availability of 3D printers, additive manufacturing that uses direct manufacture of final product are barely implemented in serial and massive production. Only a few companies use them as their basic instrument for final product manufacturing,” says one of the project’s authors, Tatiana Zaytseva.

The goal of South Ural State University master’s degree students’ project is to develop methods of implementing additive manufacturing at an industrial enterprise in order to obtain competitive advantages and a growth of import substitution share.

Algorithm for innovation implementation

In the basis of the project lies the idea to develop recommendations for industrial enterprises for introduction and usage of hi-tech novelties in the processes of product manufacture based on additive technologies, aimed at improving its technological and economical characteristics, expanding the assortment, and obtaining competitive advantages in production and product sales.

“As we are specializing in innovation project management, our team developed an algorithm for implementation of innovative methods of product manufacture based on the use of additive manufacturing. The algorithm has already passed state registration,” explains Natalia Oreshkina.

This software product based on the analysis of engineering capabilities of additive manufacturing provides a visual demonstration of dependency of the main indicators of product manufacturing on changeable parameters. The algorithm can be used in both the process of an enterprise’s strategic development and in education process.

Unique solution for industrial enterprises

“The developed algorithm will help reducing time, because this is a step-by-step development of making decisions targeted at resource saving,” emphasizes supervisor of the research group, Viktor Tomashev. “The uniqueness of this invention is in the fact that we proposed a combination of managerial and engineering solutions. Aside from engineering parameters, managerial moments are taken into account as well, as without them it is difficult to make an objective decision. All the more so when the cost of such solution is measured in hundreds of millions.”

The research of innovative methods of product manufacture based on the use of additional manufacturing, proposed by the SUSU SEM master’s degree students, will allow determining the most typical parameters and aspects of activity, influencing on the process of implementation of innovations at industrial enterprises. Thus, the process of product manufacturing at an industrial enterprise can be accelerated, creating the foundation for organizing a substantiated process of import substitution.

Results of the research

In the nearest future, the team of scientists is planning on selling licenses for the right to use the invented object of intellectual property to industrial enterprises. Moreover, results of the research will be presented at the International Conference on Systems Engineering and Engineering Management, which will be held in San-Francisco in October of 2018. Conference proceedings will be published in a scientific journal indexed in Scopus database.

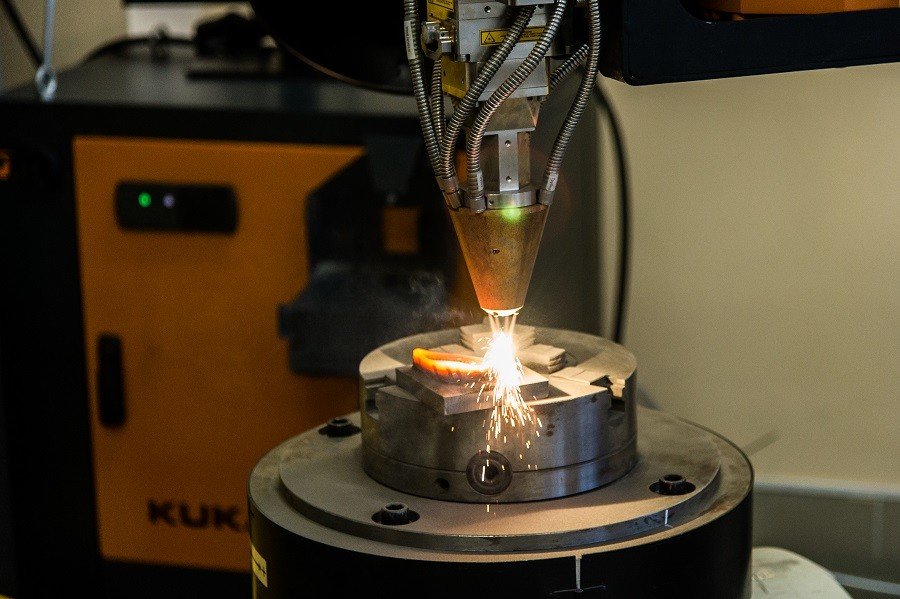

Last year, the Laboratory of Mechanics, Laser Processing and Digital Technology, which was created with participation of SMS Group Company – the world’s leading manufacturer of metallurgical equipment, was opened at South Ural State University. Employees and students of the Department of Innovation Management in Business, by cooperating with industrial enterprises within the frameworks of research works, are offering cooperation with the SUSU Laboratory for manufacturing unique products and accessories for outsourcing with the use of additive manufacturing.