Magnets have been known to humanity since long ago. In Ancient Greece the ability of some rocks to draw chunks of iron had already been discovered. Contemporary scientists found out that not only materials on the base of iron (ferrites) possess magnetic properties. Nowadays among the most powerful magnets are samarium-cobalt (or samarium) magnets. Their principal feature is high temperature resistance and preserving of their initial magnetization intensity at temperatures up to 350°С.

Associate Professor from the Department of Computer Simulation and Nanotechnology of the SUSU Institute of Natural Sciences, Andrey Sobolev (Candidate of Physical and Mathematical Sciences) together with his colleagues from the M.N. Mikheev Institute of Metal Physics of the Ural Branch of Russian Academy of Sciences (Yekaterinburg) is conducting a research of samarium magnets. His article entitled “Simulation of structure and study of the influence of Cu-doped atoms on magnetic properties of alloys of Sm-Co system for high-temperature permanent magnets” allowed Andrey Sobolev to become one of the winners of the Beginning of Big Science contest which was held by SUSU within the frameworks of Project 5-100.

Photo: Andrey Sobolev, Associate Professor of the Department of Computer Simulation and Nanotechnology of the Institute of Natural Sciences

Why does a magnet need constancy?

Magnet is a body which has its own magnetic field. Electron can be considered to be the most primitive and smallest magnet. Magnetic properties of all other magnets are determined by magnetic moments of electrons inside them. Permanent magnet is a product made of ferromagnetic material which is capable of preserving the residual magnetization after switching off the outer magnetic field.

“Nowadays permanent magnets find efficient use in many spheres of human life. Permanent magnets can be discovered in practically every apartment in various electronic and mechanical devices. They are used in medicine equipment and measurement apparatus, in various tools and in automobile industry, in direct current motors, acoustic systems, household electrical devices and in many other fields: radio engineering, instrumentation engineering, automation, telemechanics, etc. – neither of these fields can’t manage without the use of permanent magnets,” exemplifies Andrey Sobolev.

Magnetic properties are only specific to ferromagnetis, i.e. the substances which (at the temperature lower than the Curie point) are able to possess magnetization at the absence of the outer magnetic field. There are only three ferromagnetics in the Mendeleev’s table: ferrum, cobalt and nickel. Yet separately they possess quite poor magnetic properties. These properties increase if a ferromagnetic gets combined with one of rare-earth elements (for example, samarium or neodymium).

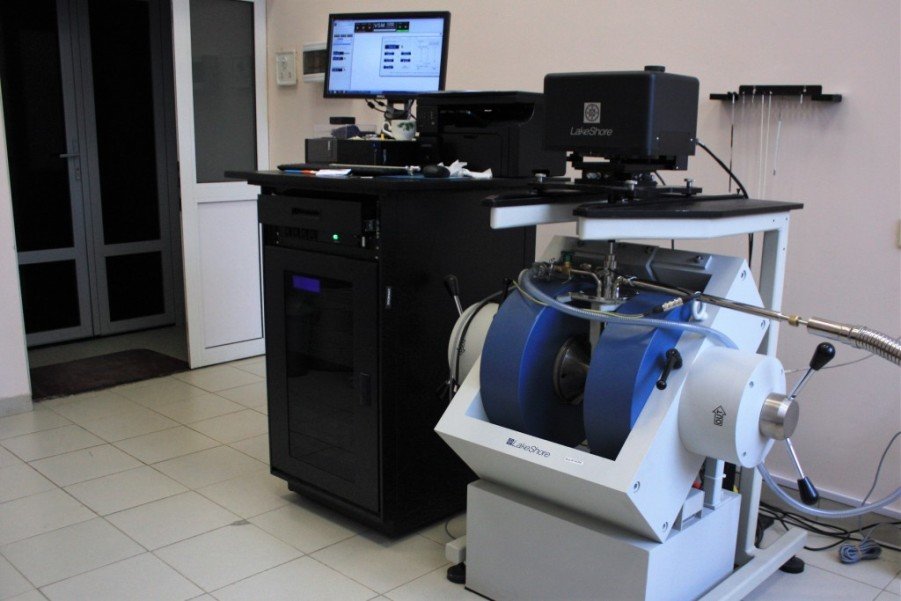

Photo: Vibration magnetometer

Samarium will solve the problem of import substitution

In contemporary production, the most popular are neodymium magnets. The originated in 1982 three-component alloy of neodymium, ferrum and boron (NeFeB) possesses an exceptional residual magnetization. Despite its small size, neodymium magnet generates a strong magnetic field; its coercitive force is very high, i.e. the magnet is resistant to demagnetizing. Self-cost of neodymium magnets is lower than of samarium-cobalt magnets, which predetermined their wide distribution in various fields of electric engineering, medicine, technology and industry.

“The problem is, the majority of neodymium mines are located in China. This country practically totally control the manufacture of ore possessing rare-earth metals. Though in Russia we have deposits of samarium. Therefore the use of samarium magnets can become a good strategy for import substitution,” assures the researcher.

Magnets with neodymium have one more sufficient disadvantage: when heated, they lose their magnetic properties. Compared to neodymium magnets, samarium magnets are capable of resisting higher temperatures. The maximum operating temperature of magnets made of samarium-cobalt alloy lies in the range from 250 to 350 Celsius degrees. Besides, samarium magnets compared to neodymium magnets are more resistant to corrosion and usually don’t require special coating. Thanks to the special corrosion resistance, precisely samarium magnets are used in strategic studies and military applications.

“Now there is a tendency to use electronic transport, electronic automobiles, electronic motors, wind-powered generators, i.e. the so-called ‘green’ energy. In such generators, temperatures are quite high and therefore neodymium magnets don’t work there because they lose their properties. In such cases, only samarium magnets can be used, as the samarium-cobalt alloy is perfectly fit for aggressive mediums and difficult exploitation conditions,” explains Andrey Sobolev.

Photo: Diffractometer

Research of samarium magnets by the Ural’s scientists

The objective of scientists of South Ural State University and the Institute of Metal Physics is in understanding the mechanism of permanent magnets. This will allow for improving their structure and properties. This requires special experiments which will be able to demonstrate what exactly should be done with these magnets to obtain the best magnetization. And even though such experiments were carried out multiple times, still experimental chemistry can’t answer the question of ‘how?’ i.e. explain the mechanism. For that, computer simulation comes to experimentalists’ aid.

“Computer simulation of materials with the use of the Theory of functional of electron density proposed by American scientists Hohenberg and Kohn is actively developing at the present time. This theory allows solving the system of Schrödinger equations which describes the behavior of separate electrons and describes the entire space in a whole. The colleagues from the Institute of Metal Physics conduct experimental part of the research; and our task is to determine magnets’ mechanism by computer simulation methods,” explains the SUSU scientist.

The method, developed by the team of scientists from the Ural universities, has already been tested on allied structures where cobalt was replaced with yttrium. The next stage will be replacing yttrium with samarium which is a heavier element. In the future, it is also planned to add copper in order to obtain better magnetization. This will allow obtaining more reliable magnets for industry and transport. In the upcoming year, results of the research are planned to be published in a high-ranked scientific journal entitled “Journal of magnetism and magnetic materials” included in Scopus Top 25%.